In the fast-paced world of industrial fabrication, the role of a welder is both technical and vital. At Chief Fabrication, welders bring together skill, precision, and a deep understanding of safety protocols to manufacture high-quality parts that meet stringent industry standards. This article provides an in-depth look into the daily responsibilities of a welder at Chief Fabrication, highlighting the craftsmanship, teamwork, and safety measures that define this essential role.

Precision Starts with Technical Mastery

Every day for a welder at Chief Fabrication begins with reviewing blueprints and technical drawings. These documents contain the detailed specifications that guide each weld, from the size and shape of the materials to the precise locations where joints must be made. The ability to interpret these plans accurately is essential, as it sets the foundation for every task that follows.

However, welder precision goes far beyond simply following a blueprint. Each weld must meet exact standards to ensure that the final product is both strong and durable. This requires mastery of various welding techniques, such as MIG (Metal Inert Gas) welding, which is commonly used for its ability to create clean, strong welds. Welders at Chief Fabrication must be adaptable, switching between techniques as project requirements change, always ensuring that the quality of their work remains consistent.

Operating high-tech equipment is another significant part of the job. At Chief Fabrication, welders utilize tools like the DAVI roller, Jetline seam-welder, and plasma cutters to achieve the precision required for each project. This equipment enables welders to handle a wide range of materials and shapes, ensuring that the finished products meet the highest standards of strength and durability.

The Importance of Equipment Maintenance

Welding requires not only skill but also reliable, well-maintained equipment. A key responsibility for welders at Chief Fabrication is ensuring that the tools they use are in top working condition. Regular maintenance routines are essential for preventing equipment failures that could halt production or compromise the quality of the welds.

Welders perform routine checks on their machinery, troubleshooting issues as they arise and carrying out minor repairs when necessary. This proactive approach helps maintain smooth operations, ensuring that production schedules are met and that there are no interruptions in the workflow. Equipment maintenance is also directly linked to safety, as faulty machinery can lead to dangerous situations in the workplace.

By taking care of the tools and machinery, welders contribute to both the efficiency and safety of the production process, ensuring that each job is completed on time and to the highest standards.

Collaboration for Consistent Quality

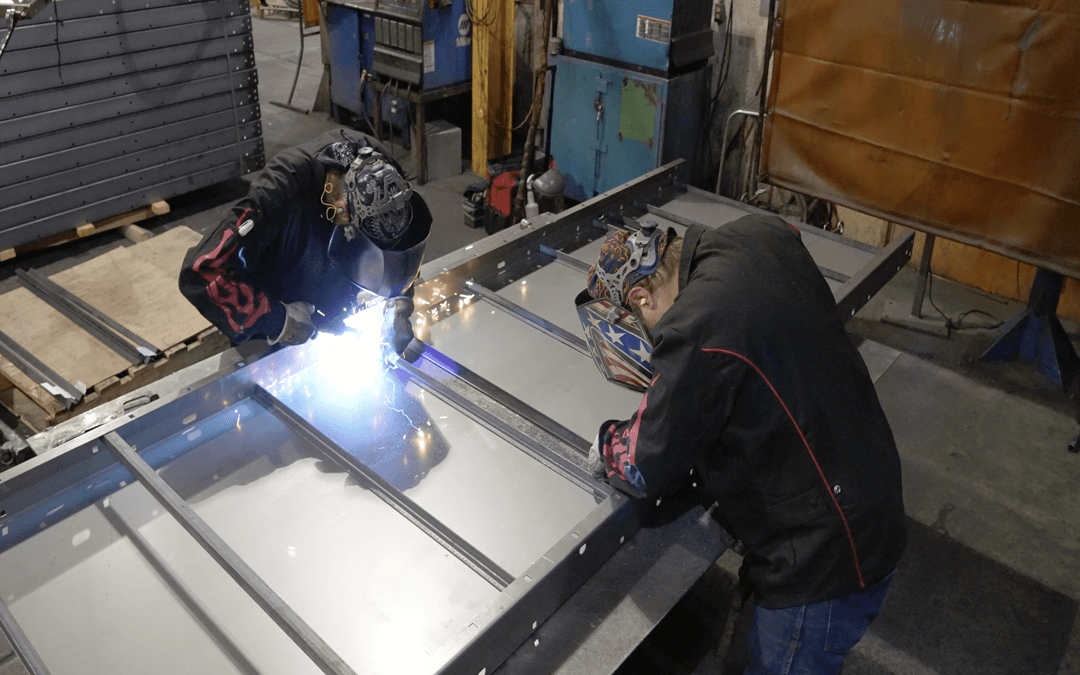

Though welding can seem like a solitary task, teamwork, and communication are vital to success. At Chief Fabrication, welders work closely with supervisors, engineers, and other team members to ensure that each project moves forward smoothly. Whether it’s discussing project specifications, adjusting timelines, or solving technical challenges, effective collaboration helps maintain a consistent workflow and high-quality output.

Teamwork is also crucial when it comes to aligning safety measures. Welders communicate regularly with their teams to identify potential hazards, coordinate safety protocols, and ensure that everyone is adhering to the strict safety standards set by Chief Fabrication. This collaboration not only helps protect individual workers but also fosters a culture of accountability and care across the entire production team.

The ability to work well with others, while maintaining a focus on detail and precision, is what allows welders to consistently produce reliable, high-quality parts.

Commitment to Safety and OSHA Compliance

In any industrial setting, safety is a top priority, and at Chief Fabrication, welders adhere to rigorous safety standards to protect both themselves and their colleagues. OSHA (Occupational Safety and Health Administration) regulations form the basis of the safety protocols followed at the plant, but welders also adhere to additional internal safety measures to account for the specific hazards of welding.

Welders must consistently use personal protective equipment (PPE), including welding helmets, gloves, and protective clothing. These items are essential for shielding welders from the extreme heat, sparks, and ultraviolet radiation produced during the welding process. In addition, welders are trained to recognize potential hazards, such as faulty equipment or improper ventilation, and to take immediate action to mitigate those risks.

Welders must be constantly vigilant, ensuring that proper ventilation is maintained and that they stay hydrated and alert throughout their shifts. Recognizing and addressing these dangers is crucial for maintaining a safe and productive work environment.

At Chief Fabrication, safety is more than just a set of protocols—it’s a core part of the company culture. Every welder is responsible for maintaining a safe workplace, both for themselves and for their colleagues. This commitment to safety ensures that the production process runs smoothly without compromising the well-being of the workforce.

Welding as a Craft and a Career

Being a welder at Chief Fabrication is about more than just producing parts. It’s about mastering a craft, continuously honing skills, and contributing to the success of a company that values quality and precision. Welders are the backbone of the production process, creating the high-quality, durable components that Chief Fabrication’s customers rely on.

Welding requires not only technical expertise but also a passion for the trade. At Chief Fabrication, welders are encouraged to continuously improve their skills, whether by learning new welding techniques or gaining proficiency with the latest equipment. This commitment to professional development not only benefits the welders but also enhances the company’s ability to deliver top-tier products to its clients.

For welders, there is a sense of pride in knowing that the parts they create will be used in a wide range of industries, from construction to manufacturing. Every weld is a reflection of their skill and dedication, and every finished product is a testament to the teamwork and precision that defines the welding process at Chief Fabrication.

A Role That Goes Beyond Welding

Ultimately, the role of a welder at Chief Fabrication is about more than just joining metal pieces together. It’s about contributing to a larger mission of producing high-quality, reliable products that meet the needs of a diverse range of industries. Whether working on a large-scale construction project or producing custom components for specialized machinery, welders at Chief Fabrication take pride in their ability to deliver exceptional results.

The combination of technical skill, attention to detail, and commitment to safety ensures that each project is completed to the highest standards. With the support of a collaborative team and state-of-the-art equipment, welders at Chief Fabrication are well-positioned to meet the challenges of a constantly evolving industry.

At Chief Fabrication, we are committed to producing high-quality, durable products that meet the needs of our clients. Contact us today to learn how our skilled welders and advanced manufacturing techniques can help bring your project to life.