As a producer of Ethanol, Chief Ethanol Fuels is consistently focused on processing corn to extract the most out of each kernel. Our team has been focused on upgrading our Lexington, NE location so that it has the capability like our Hastings plant to produce ethanol fuel, high-quality animal feed products, and high-value crude corn oil.

The team is excited to announce that the Corn Oil Extraction System (COES) is now fully operational at the Lexington ethanol plant. Our plants use locally sourced Nebraska corn to produce ethanol that is blended with gasoline and used as a transportation fuel. This is a renewable process that supports local farmers and businesses and allows the United States to import less petroleum oil into the country.

The corn dry grind ethanol process uses the starch component in corn to produce ethanol. The other corn components such as protein, fat, fiber, and other nutrients are passed through the process to make high-value animal feed co-products.

The corn oil extraction system allows the removal of a fraction of the incoming corn oil to be sold as a separate coproduct. Crude corn oil can be used to make other transportation fuels such as renewable diesel and biodiesel as well as used as an animal feed ingredient.

For many consumers, golden corn oil serves as one of the most visible signs of the corn refining industry. Although corn oil represents a relatively modest share of the ingredients produced by corn refiners, its household uses to illustrate the vast array of food and other products derived from our nation’s most abundant crop.

By removing free fatty acids and phospholipids from crude corn oil, the oil refining process gives corn oil one of the qualities that cooks value most: Its excellent frying quality and resistance to smoking or discoloration. Corn oil is regarded highly for its functionality, exceptional flavor, affordability, and health benefits. It is high in energy, easily digestible, provides Vitamin E, and is a rich source of polyunsaturated fatty acids, which help regulate blood cholesterol levels and lower elevated blood pressure.

Corn oil’s unique chemistry also makes it an important ingredient in a range of products not associated with cooking. For example, corn oil, sometimes called “zea mays oil,” is often found in soaps, shampoos, household cleaners, and personal care products, such as cosmetics.

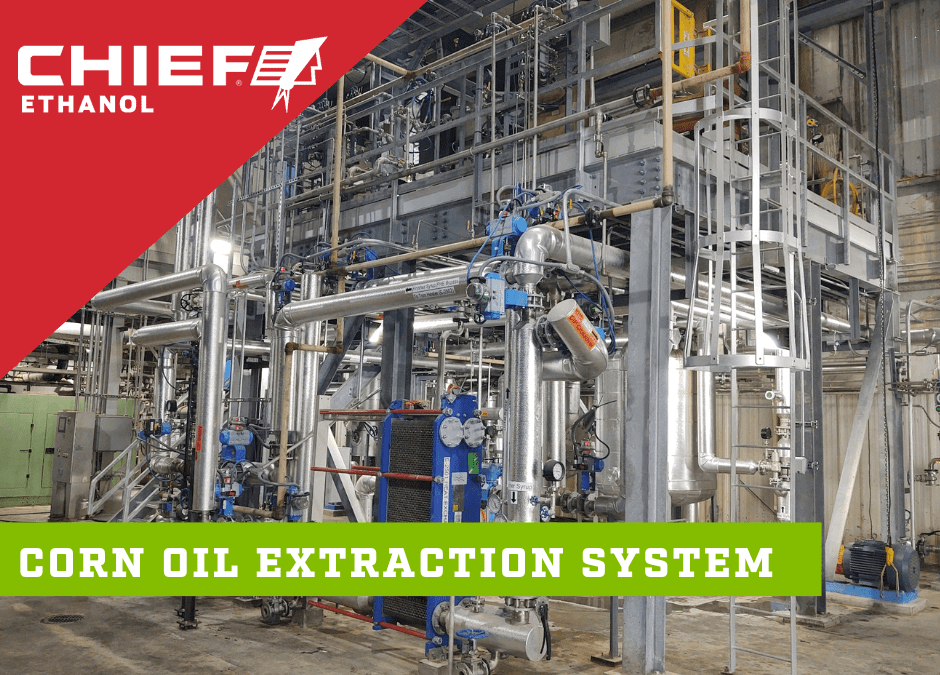

The project to install the Corn Oil Extraction System was started in August 2021. During the first few months, the team dedicated their focus to removing old equipment in order to make room and prepare the site for the new processing equipment and storage tanks. The COES was designed by Chief Ethanol in conjunction with an outside engineering firm, Process Design, and Service, that specializes in building corn oil extraction systems. The construction and installation of the new equipment were managed and executed by Chief Ethanol personnel along with outside contractors, most notably Krueger Construction and Flash Electric LLC. The mechanical and electrical portions of the project were completed in early June 2022. Chief Ethanol personnel worked in conjunction with an outside systems integrator, Mescada, to commission the COES control system and integrate it with our current operating system. The construction and commissioning process was completed in late June. After a scheduled plant shutdown in early July, the system was brought online in the middle of July.

After a highly involved construction and commissioning process, the system came up very well. Clean oil that was within product specifications was extracted within the first two days of operation and the system was fully online and running in automatic control by the end of the first week.

There are a number of products that are made from corn and the byproducts of corn oil processing. Whether it’s ethanol or high-quality animal feed, Chief Ethanol Fuels offers many different products to our customers.